The new Australian Standard for racking design (AS4084.1.2023) and operation (AS4084.2.2023) was released in 2023, and marks the new standard for warehouse and logistics operators. No new racking should be installed — or old racking reconfigured — that does not fit within the new standard.

Racking purchased in 2022 or earlier and meets the 2012 standards does not need to be replaced. However, if it is reconfigured, moved, or shows signs of fatigue or damage, the racking must comply with the new standards AS 4084-2023.

Racking that pre-dates the 2012 Australian Standards is recommended to be updated to be considered compliant.

APEX Racking and Global Industrial racking components manufactured between 2012 and 2023 are backward compatible with the new 2023 racking standards.

If you’re unsure whether your warehouse racking meets the new standards, ask a Global Industrial team member about booking a racking inspection to ensure it’s up to code.

What’s new in AS 4084-2023 compared with 2012?

Most of the new standards relate to the engineering and manufacturing of racking, codifying the highly technical specifications to ensure that all racking sold in Australia meets the safety parameters. Details relate to ductility, structural performance factor, and deflection limits.

The 2023 standards also offer an updated seismic mass coefficient, which affects the calculation of seismic loads on storage racks (such as for installation in an earthquake-prone area).

AS 4084-2023 refers explicitly to selective ‘Steel Pallet Racking. The 2023 Standards exclude drive-in racking, cantilever racking, mobile racking (such as longspan), and shelving. Selective pallet rack footplates must have a minimum of two (2) floor anchors installed and, in some cases, more. The 2023 Standards also clarify requirements for racking used outside.

Key takeaways for operators (asset owners) in AS 4084-2023

- Mandatory formal annual inspections are required, with the audit completed by a ‘Competent Person for formal inspections’ which is someone who has worked in the industry as a racking designer, engineer or installer or have similar experience with steel storage racking

- Documentation, including manuals, racking inspection audits and repair logs, needs to be maintained for the life of the racking system.

- Upright protectors at least 400mm high should be positioned along gangways, on the frame at the end of rows, and at aisle cross-sections.

- Backing mesh must be installed to protect pedestrians behind single sided racking

- Load signage requirements must be permanent, corrosion-resistant, no smaller than A3, and the font must be at least 20 mm in height.

- Height constraints: where the end frame is adjacent to a trafficable aisle, it must extend past the top load beam by at least 50% of the pallet height.

How long does a racking inspection take and what are the costs involved?

A proper racking inspection should at a minimum take a few hours and depending on the facility size, the inspection can span multiple days. Costs may range from a few hundred dollars to thousands depending on scale and whether any raised equipment is required.

Are inspections required every 12 months or once per calendar year?

Informal Inspections are the responsibility of the asset owner and should be conducted on a daily or weekly basis.

Formal Inspections shall be conducted at least every 12 months unless risk assessments require it to be taken more frequently, such as every 6 months

What are the new requirements for racking used outside?

Racking in external environments shall comprise components which are either hot-dip galvanised (HDG) or manufactured from pre-galvanised coil. If powder-coated racking is installed externally, the frequency of formal inspections shall be increased in order to monitor the degradation in the protective coating over time.

Racking shall be installed on a concrete floor. Alternate substrates such as asphalt/bitumen are NOT suitable.

Is my selective pallet racking signage compliant with the new AS 4084-2023 standard?

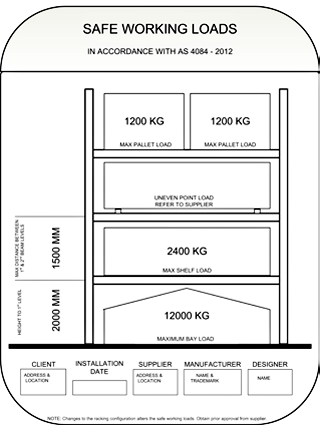

If racking was installed before 2023 and compiled to AS4084.2012 and remains unchanged then it is likely that your load signs are compliant. If your racking was installed from 2023 onwards, then under AS 4084-2023, the Safe Working Load signage shall always reflect the current configurations and should be updated following any modifications. Part of your annual inspection includes checking whether your racking load signage is compliant with the 2023 Standards and includes:

- The unit load limit

- Beam load limit

- Bay load limit

- Designer’s name

- Manufacturer’s name

- Supplier’s name

- Installation date

- Customer’s name

- Maximum distance from ground to first beam level

- Maximum distance from first to second beam level

- Tolerance grade

An example of safe working loads signage according to AS 4084-2023:

Image Source: https://www.safework.nsw.gov.au/resource-library/pallet-racking-guide (Accessed 20 Feb 2024)

Do the AS 4084-2023 Standards need to be applied to my existing racking?

Racks installed before 2023 that adhere to the design requirements of the 2012 standards don’t require replacement. If reconfigurations, relocations, or indications of fatigue or damage, the racking must comply with the updated standards, AS 4084-2023.

What should I do if I’m unsure whether my racking is compliant?

Contact us to arrange a pallet racking inspection as soon as possible. We’re here to help you avoid common pallet racking hazards in your workplace.

Please reach out to the experts at Global Industrial if you have any concerns because it’s always better to be safe than sorry.